Conductive Cotton: The Future of E-Textiles?

Researchers at Washington State University have developed a fiber with the flexibility of cotton and the conductive properties of a polymer. This is an impressive development when it comes to the advancement of e-textiles and wearables.

Image: Dean Hare, WSU Photo Services

The researchers were able to test these cotton-like fibers with an LED light power source and one that sensed ammonia gas. You can find out more about their findings in this study.

We are still a long way from the integration of these fibers in wearables, but the hope for this advancement is clear—make it easier to weave e-textile technology directly into everyday clothing. We’re not too far away from this reality.

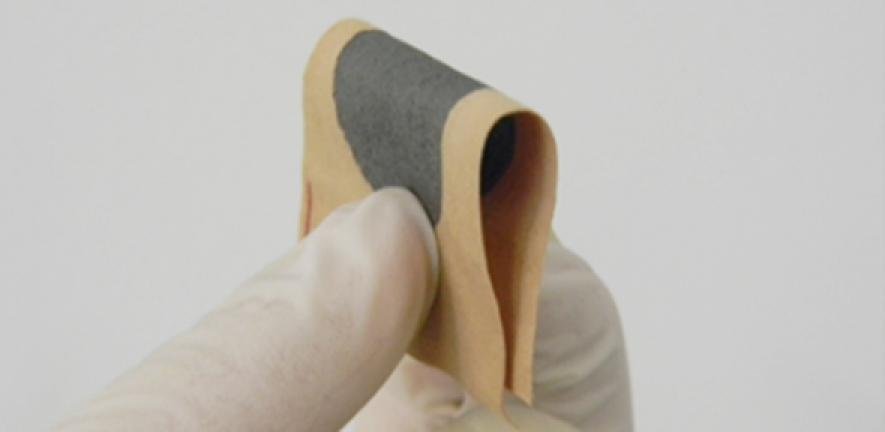

Now, this is something that has been explored in the past—albeit with a different approach. Researchers at the University of Cambridge explored the idea of conductive cotton back in 2016. Along with Jiangnan University in China, the researchers were able to create a wearable motion sensor that consisted of graphene ink on cotton fabric. The approach may be different, but the idea to make a non-conductive material conductive is the same. The graphene flakes are adhered to the cotton fabric, then treated with heat to boost electrical conductivity. The bonus to this method is that the conductivity can be retained with several washes. Additionally, Dr. Felice Torrisi, who developed this process, notes that graphene is “more sustainable, more chemically compatible with cotton, and less costly” than other conductive inks.

Image: University of Cambridge

The alternative to creating a novel fiber or adhering a conductive layer to fabric is to coat yarn in a conductive material. This material, called MXene, makes the yarn electromechanically active and allows the fibers to maintain their flexibility. The researchers who have worked on this project claim that this coated yarn can be knitted using a standard industrial knitting machine, mainly because of its durability. The team also claims that with this method, the material performs better, and the yarns can be manufactured on a larger scale than similar fibers. As for application areas, this MXene yarn can add energy storage capabilities, sensing, electromagnetic interference shielding, and many other interesting properties to textile-based products.

Ultimately, everyone’s goal is to seamlessly integrate e-textile technology into our clothes and improve lives. Fabrics should be made with this technology integrated from the get-go, instead of applying it to textiles later down the road. Although, there are clear benefits to both. We want to see this technology impact people at every touchpoint of life, and one way to do that is to ensure the technology is already a part of the fabric ahead of apparel manufacturing. Perhaps it can be coupled with programmable weaving, which would further expedite manufacturing time.

We are excited to see how this one pans out, and we hope it is a success!

More insights and interesting reads:

Programmable Weaving for E-Textiles

What Are Flexible Electronics?