What Are Smart Textiles?

There is a lot of information floating around regarding smart textiles. However, with so many other similar terms floating around—navigating this industry and how the technology works can be well, difficult. We are going to define exactly what a smart textile is, tell you a bit about the history of this technology, the meaning of active versus passive smart textiles, and the various application areas. Read on to (hopefully) clear up any confusion you may have!

Download our E-Book by opting in to our Mailing List for more on E-textiles and Smart Textiles:

Defining smart textiles

Smart textiles, also known as electronic textiles (e-textiles) or smart fabrics, are textiles that contain electronic components and enhance the features of wearables, automobiles, and other products. They are either made into a textile-based product, or created with the intention of being integrated into a textile.

There are some other terms to be made aware of. And while they can be used interchangeably in some cases, we avoid doing so to prevent any further misinformation or confusion. Here are some other words you may see floating around in place of smart textiles:

Technical textile

Intelligent textile

Functional material

Functional textile

Functional fabric

Nano-fabric

Electronic fabric

Smart fibre

Soft circuit

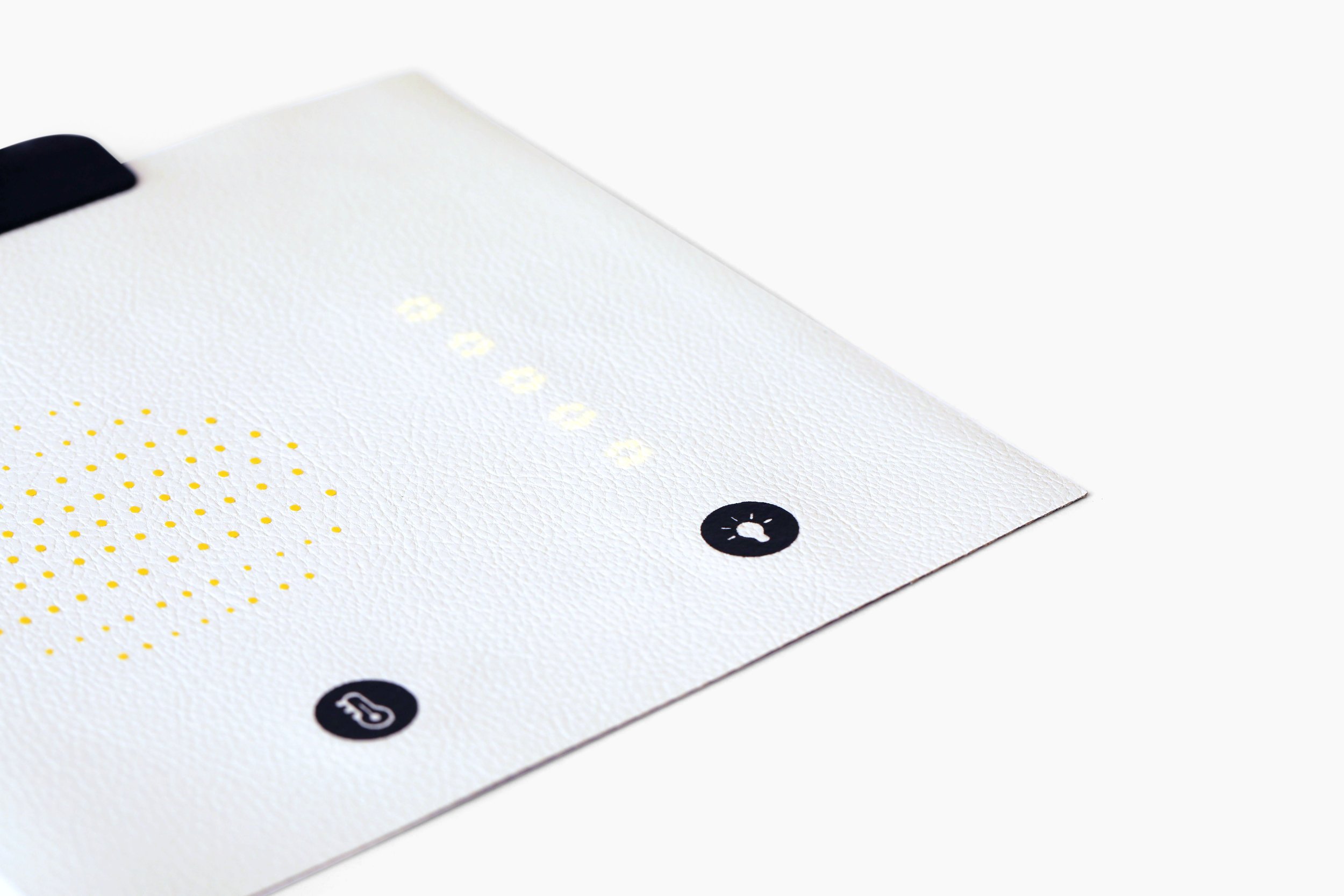

Smart textiles, such as our Loomia Electronic Layer (LEL), can provide a wide variety of functionality to soft goods including heating, lighting, and sensing technology. It is important to note that some smart textile technologies, like the LEL, can be integrated into other types of surfaces such as wood and polycarbonate.

History of smart textiles

Here are some key moments in the history of smart textiles. You can read more here.

1600 — Early conductive threads are said to date back to the Elizabethan era when gold threads were woven into garments for a gleaming accent. Now, we often use silver, or nickel threads for conductivity, but the concept of metallic threads has existed for centuries for decorating garments.

2007 — Leah Buechley develops the Lilypad, a microcontroller made specifically for textiles. (Adafruit later makes its own version called the Flora)

2014 — Dupont presents their stretchable, conductive ink at Printed Electronics 2014

2014 — The MIT Biosuit creates a strong use case for e-textile in industry

2015 — Google’s Project Jacquard directs tech eyes to e-textiles at Google I/O

2015-today — Studios such as Wearable Experiments, Interwoven and The Crated create practices around e-textiles and making invisible wearable tech. Loomia is born.

Passive vs. active smart textiles

Image: Unsplash

There are two main types of smart textile technology; passive and active. Often deemed the “first generation” of smart textiles, passive smart textiles are those that have functionality beyond that of a traditional woven textile. However, let it be known that passive textiles generally do not adapt as a result of the information they sense. In other words, the textile is not altered when environmental conditions change. Take for example, a cooling fabric that can help to regulate your temperature; but it does not actively provide coolness. The fabric simply helps you to evaporate liquid more quickly due to the construction of the textile. The same goes for apparel and other goods with UV protective, antimicrobial, and conductive/anti-static nanotechnologies.

Here are some examples of passive smart textile products:

Cosmo - A leader in fabrics for footwear, Cosmo utilizes Microban technology to add antimicrobial properties to their textiles; resulting in less odor.

Sunbrella - Sunbrella’s outdoor performance fabrics are treated with UV-stabilized pigments to help maintain lasting color and durability under the harsh rays of the sun.

Herculite - A manufacturer of PVC composite textiles, Herculite fabrics are made for applications that require a high level of durability, such as military, healthcare, and marine, using their unique weaving technology.

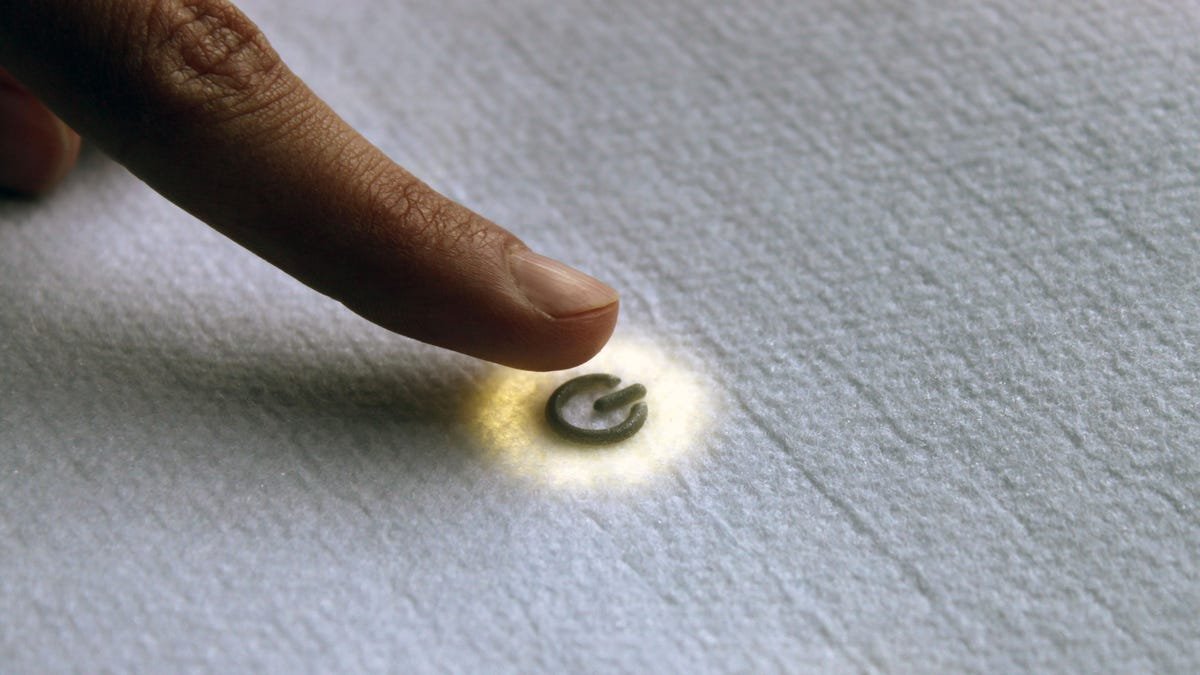

Active smart textiles are those that adapt and change their functionality in response to changes in the external environment or in response to a user input. These materials may change shape, store and regulate heat, and be applied to a wide range of flexible applications. While passive textiles generally rely on their structure to function, active textiles generally utilize electricity, which can support actuators and sensors. These electronic components allow the smart fabric to sense touch and temperature, as well as process and interpret a myriad of information pertaining to the external environment. They are a crucial part of smart textile manufacturing.

Here are some examples:

Loomia Electronic Layer - The Loomia Electronic Layer is a soft, flexible circuit that can enable next-generation products in wearables, automotive, and beyond.

HeiQ Smart Temp - HeiQ’s Smart Temp fabric features intelligent thermoregulation technology that is triggered by the body’s temperature, and cools the user down as a result.

Gentherm - Gentherm manufactures a few different technologies, each with a different purpose. Their ClimateSense® technology is built on an algorithm that changes the temperature in a vehicle or medical wearable depending on the user’s unique preferences.

Key application areas

There are several applications of passive and active smart textiles. However, for the sake of this particular article, we are going to zero-in on those in wearable technology, outdoor apparel and accessories, and automotive interiors.

Passive

The most common application of passive smart textiles is in outdoor apparel and medical wearables. We provided you with the example of a cooling textile already, but these textiles can be used in more ways than one. Here are some other possible functions of passive textiles:

UV protective - Passive elements, such as optical brighteners and UV absorbers, are added to fibers to create sun-protective properties. When used in combination with other technical components, these materials can be very effective at preventing skin damage and other related conditions that are the result of sun exposure.

Antimicrobial - Antimicrobial composite coatings are a popular commodity in the textile industry, especially in the manufacturing of activewear. These coatings are effective in preventing the growth of bacteria that is produced from perspiration. While these coatings may be saving your clothes, they are certainly not saving the planet. One would think that the chemicals in the coatings are a concern, but the problem actually lies in the disposal of these textiles.

Active

Active smart textiles have a wide range of capabilities, and possess many traits that passive smart textiles do not. As mentioned earlier, active textiles adapt and change their functionality in response to the external environment. These materials produce an “action” as a result of the information obtained (think of it this way: active equals action). The following are just a few examples of what active textiles can do:

Thermoregulation - Among the most common applications of active textiles is in outerwear; specifically, wearables that regulate the body’s temperature. Earlier this year, we at Loomia produced a heated jacket. Our LEL (Loomia Electronic Layer) was integrated directly into the garment, providing a subtle, yet comfortable climate for the wearer. This is a particularly exciting development, as this technology could one day be used to help the elderly and those with medical conditions stay warm (and, for a relatively affordable price).

Seat sensing and heating - The automotive industry is, perhaps, the largest to implement active smart textiles. There are several concepts currently in the development process, but one that stands out most is the ability to distinguish a car’s driver by their size and weight through pressure sensors. However, one application that several of the world’s largest car manufacturers (and consumers alike) are particularly fond of is heated seats. Yes, that wonderful setting that warms your soul after shoveling out your car is a product of smart textiles!

The e-textiles/smart textiles world can be rather complex and multifaceted. However, don’t let this intimidate you and keep you from learning more! With that being said, we hope we have made the topic of passive and active smart textiles a bit easier to digest.

Feel free to check out our other blog posts on e-textiles to expand your knowledge even more: