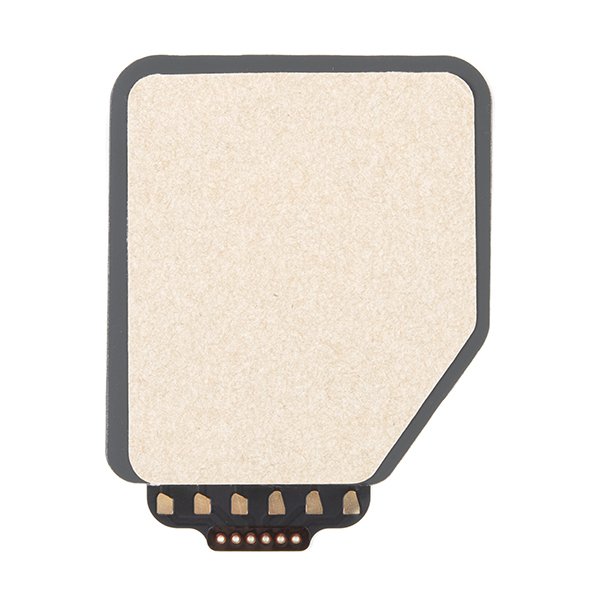

Mega Soft Pressure Matrix / Thin Film Pressure Sensor

Discover LOOMIA’s Thin Film Pressure Sensor—flexible, durable, and accurate for measuring pressure in wearables, robotics, and medical devices. The Loomia Mega Pressure Matrix has six leads, allowing you to map which point you are at in the 3x3 matrix and get a pressure mapping over a surface. Each area has an analog readout that varies depending on the weight of the item on the pressure sensor. Generally, sensor values will read from 500K Ohms to 100 Ohms depending on the force put onto the sensor.

Loomia parts are designed to be easily soldered together, and work well with popular micro controllers like Arduino Nano and Teensy. The system revolves around Loomia's custom interconnect, which allows for a simple connection between buses. The interconnect can be soldered to headers for easy breadboarding. From fabric to wood, Loomia components can stick onto a range of materials, making your prototypes look clean and polished.

Note: There are a number of operating procedures to be aware of before using Loomia products. This includes directions to not wash or sew any of the parts. Make sure to check the Datasheet at www.loomia.com/resources to get more information on this component.

Discover LOOMIA’s Thin Film Pressure Sensor—flexible, durable, and accurate for measuring pressure in wearables, robotics, and medical devices. The Loomia Mega Pressure Matrix has six leads, allowing you to map which point you are at in the 3x3 matrix and get a pressure mapping over a surface. Each area has an analog readout that varies depending on the weight of the item on the pressure sensor. Generally, sensor values will read from 500K Ohms to 100 Ohms depending on the force put onto the sensor.

Loomia parts are designed to be easily soldered together, and work well with popular micro controllers like Arduino Nano and Teensy. The system revolves around Loomia's custom interconnect, which allows for a simple connection between buses. The interconnect can be soldered to headers for easy breadboarding. From fabric to wood, Loomia components can stick onto a range of materials, making your prototypes look clean and polished.

Note: There are a number of operating procedures to be aware of before using Loomia products. This includes directions to not wash or sew any of the parts. Make sure to check the Datasheet at www.loomia.com/resources to get more information on this component.

Discover LOOMIA’s Thin Film Pressure Sensor—flexible, durable, and accurate for measuring pressure in wearables, robotics, and medical devices. The Loomia Mega Pressure Matrix has six leads, allowing you to map which point you are at in the 3x3 matrix and get a pressure mapping over a surface. Each area has an analog readout that varies depending on the weight of the item on the pressure sensor. Generally, sensor values will read from 500K Ohms to 100 Ohms depending on the force put onto the sensor.

Loomia parts are designed to be easily soldered together, and work well with popular micro controllers like Arduino Nano and Teensy. The system revolves around Loomia's custom interconnect, which allows for a simple connection between buses. The interconnect can be soldered to headers for easy breadboarding. From fabric to wood, Loomia components can stick onto a range of materials, making your prototypes look clean and polished.

Note: There are a number of operating procedures to be aware of before using Loomia products. This includes directions to not wash or sew any of the parts. Make sure to check the Datasheet at www.loomia.com/resources to get more information on this component.

Features

Mega Pressure Sensor 3x3 Matrix: Like the mini pressure sensor, but bigger! Our 3x3 mega pressure matrix has 6 leads, allowing you to map which point you are at in the 3x3 matrix and get a pressure mapping over a surface. Each area has an analog readout that varies depending on the weight of the item on the pressure sensor. Generally, sensor values will read from 500Kohms to 100ohms depending on the force put onto the sensor.

From stretchy serpentine buses to pressure sensors, LOOMIA has developed a suite of Parts for your latest prototype. Our Packs & Parts are designed to be easily soldered together, and work well with popular micro controllers like Arduino Nano and Teensey. The system revolves around our custom interconnect, which allows for a simple connection between buses. The interconnect can be soldered to headers for easy breadboarding or to JST connectors for Qwicc compatible connections.

Check out our blog or our Instructables page for useful tutorials on how to integrate LOOMIA Packs & Parts into your latest project.

Bend Radius Limitation: N/A

Thickness: Approx. 20 mils

Operating Voltage Range: 3.7V - 5V

Pressure Range: 0.2lbs. - 10lbs.

Component Dimensions: 5in x 6.5in

Sensing Area Dimensions: 3in x 3in

Thin Film Pressure Sensor Solutions by LOOMIA

Thin-film pressure sensors are often printed onto kapton or polyester film to provide force-sensitive resistor (FSR) sensing properties in a thin profile. Many of these sensors use a series of conductive inks to make the sensor function. Loomia sensors are not a thin film sensor exactly, but serve a similar function and also include the benefit of multi-axis flex. Thin-film pressure sensors, such as the Loomia Mega Pressure Matrix, are used in applications that demand a balance of high sensitivity, compact form factor, and versatility, while also ensuring reliable mechanical performance across various operating conditions.Thin-film pressure sensors are crucial in rapidly growing industries such as wearable technology, robotics, medical devices, and wellness, where their precision, flexibility, and reliability are essential.In wearable technology, thin-film pressure sensors are integrated into smart clothing to monitor pressure distribution, detect movement patterns, and enhance user comfort.In robotics, they provide tactile feedback in robotic hands and grippers, enabling precise object manipulation and improving human-robot interaction in industrial automation and assistive robotics. Within the medical field, thin-film pressure sensors are used in applications such as prosthetics, pressure ulcer monitoring, and rehabilitation devices, where accurate pressure measurement is critical for patient care and therapeutic outcomes.The Loomia Electronic Layer (LEL) is an alternative to traditional thin film products. We use a conformable stackup of materials, which impacts the performance and mechanical features of the product. Our sensors are often more drapable and softer than traditional thin film sensors. For both thin film components and our sensors, the performance largely depends on the thin films used, which possess different properties and structures to achieve accurate, sensitive, and reliable detection. The Loomia Mega Pressure Matrix has six leads, allowing you to map which point you are at in the 3x3 matrix and get a pressure mapping over a surface. Each area has an analog readout that varies depending on the weight of the item on the pressure sensor. Generally, sensor values will read from 500K Ohms to 100 Ohms depending on the force put onto the sensor.

FAQ:

General Questions

1. What is a thin-film pressure sensor?

A thin-film pressure sensor is a flexible and lightweight sensor designed to measure pressure distribution across a surface. These sensors are commonly printed on materials like Kapton or polyester film and use conductive inks to provide force-sensitive resistance (FSR) properties.

2. How is the Loomia Mega Pressure Matrix different from traditional thin-film pressure sensors?

Unlike standard thin-film pressure sensors, the Loomia Mega Pressure Matrix offers multi-axis flexibility, making it softer and more drapable. Instead of relying purely on thin-film technology, LOOMIA uses a conformable stackup of materials to enhance performance, durability, and mechanical adaptability.

3. What industries use thin-film pressure sensors?

Thin-film pressure sensors are widely used in wearable technology, robotics, and medical devices. They provide accurate pressure measurement and feedback in applications such as smart clothing, robotic grippers, and prosthetics.

Product-Specific Questions

4. What is the Loomia Mega Pressure Matrix, and how does it work?

The Loomia Mega Pressure Matrix is a flexible and durable pressure sensor that enables precise measurement over surfaces. It features a 3x3 pressure mapping grid with six leads, allowing users to determine pressure distribution with analog readouts that vary depending on the force applied.

5. What are the technical specifications of the Loomia Mega Pressure Matrix?

The sensor outputs resistance values ranging from 500K Ohms (light pressure) to 100 Ohms (heavy pressure), offering a wide range of force sensitivity. It provides fast, consistent, and precise pressure readings.

6. How does the Loomia Electronic Layer (LEL) compare to other thin-film sensors?

The Loomia Electronic Layer (LEL) differs from traditional thin-film sensors by offering greater flexibility and drapability. While both sensor types depend on the properties of their thin films, LOOMIA’s stackup approach provides a softer and more adaptive material solution.

Application-Based Questions

7. How are thin-film pressure sensors used in wearable technology?

In smart clothing and wearables, thin-film pressure sensors monitor pressure distribution, detect movement patterns, and enhance user comfort. They help measure forces applied to the body, improving performance tracking and ergonomic design.

8. What role do thin-film pressure sensors play in robotics?

In robotics, these sensors provide tactile feedback in robotic hands and grippers, enabling precise object manipulation. This is especially important for industrial automation, assistive robotics, and human-robot interaction.

9. How are thin-film pressure sensors used in the medical field?

Thin-film pressure sensors are critical in prosthetics, rehabilitation devices, and pressure ulcer monitoring. Their accuracy ensures proper force distribution, improving patient care and therapeutic outcomes.

Technical & Integration Questions

10. How can I integrate the Loomia Mega Pressure Matrix into my project?

The Loomia Mega Pressure Matrix can be integrated into various systems using its six leads and analog readout, allowing users to track force changes across a 3x3 pressure mapping grid. It works well with embedded electronics, microcontrollers, and pressure-sensitive applications.

11. What factors affect the performance of thin-film pressure sensors?

Performance depends on the type of thin film used, its material properties, and structural design. Factors such as sensitivity, mechanical flexibility, and durability determine how well the sensor functions in different environments.